Welding Automation for Production and Profitability

Welding automation requires the use of machines to raise speed and precision while producing top quality welds. Methods are really simple to integrate in a production environment and cut the risk of errors and inconsistent welds, leading to higher productivity. This approach allows companies for being more beneficial to our environment and help end the call to send jobs overseas. For companies over a tighter budget, there is a substitute for rent or lease various kinds of welding related equipment.

When Quality Welds are Critical. Welding is among the most complex manufacturing processes. Both manual and automated welding has their distinct advantages. For many assemblies, manual fusing can always be the ideal alternative. However, welding automation is often a recommended process where quality of the joint is important. It is also a possible option when soldering done repeatedly on same parts.

Semi-Automatic vs. Fully Automatic. There's 2 categories of welding automation namely, semi-automatic and fully automatic. In semiautomatic soldering, parts loading in to the soldering fixture, is really a manual process, while a weld controller keeps motion of torch and stillness from the parts at preset parameters. Once the fuse is finished the operator removes the assembly and repeats the procedure. In fully automatic soldering, a personalized machine or group of machines loads the work-piece, places the part or torch in position and completes the weld. Your machine also monitors quality of the weld and unloads the welded product. A few quality checks may also be designed in to the machine. Firms that assemble products in limited quantities but must correct welds can benefit from a semi-automatic system.

The Benefits of Welding Automation. Welding automation offers four distinct advantages which include quality, increased productivity, decreased labor costs, and fewer wastage. Quality achieved by combining mechanized torch and part motions with electronic recall of parameters. Through the elimination of the human being reason in the welding process both semi-automatic and fully automatic systems assist output. With high speeds and minimal setup time, automated soldering systems can readily outpace manual soldering.

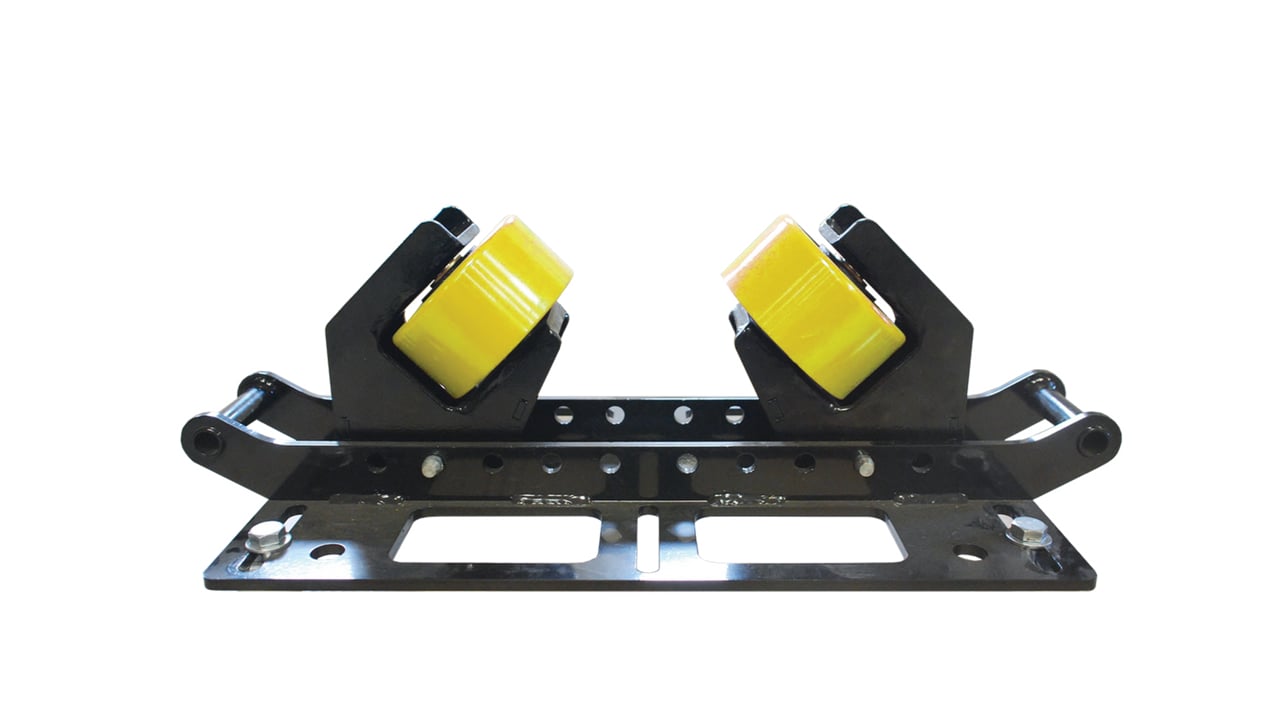

Welding Automation Apparatus. Welding automation includes several systems offering positioners, manipulators, turning rolls, bed rollers, cutting machines, wire feeders, and remote monitoring, for example. A soldering positioner is often a convenient aide to improve productivity and quality. With the help of a positioner starting work-pieces on the best possible positions can increase productivity by up to 70 percent. In addition, it permits ergonomic working comfort, that's essential for welders that otherwise may work in stressful environments.

For additional information about cable reel rollers web portal: check here.